WHITE RABBIT ANIMATION

Welcome. I'm Emma Windsor - an animation director, animator, designer and maker, who works in stop motion and motion design.

This site represents my own commercial work in stop-motion, puppet & model making, character design and motion design for clients large and small, including: Legal & General; Bristol Festival of Puppetry; Urban Fresh Foods and the BBC. See Portfolio for a selection of works, and Reel for highlights and breakdowns.

01/07/2022

Skinning is the process of applying the outer shape and clothing to the puppet’s armature to create the character. Essentially this breaks down into two stages: the interiors, which give the ‘muscle’ to the puppet; and the exteriors, which provide the clothing, accessories and other character details. For this puppet, I elected for plug-in silicone hands and boots, due to the pliability and reliability of the material. However, for the main inner body, I chose foam and polyester fibre as these are inexpensive materials that have good workability and flexibility. It was important to me that the visual aesthetic of the character was highly textured to place emphasis on the tactile, handmade nature of the puppet. Textiles with good stretch and fabric details therefore made the perfect choice for the exteriors.

13/06/2022

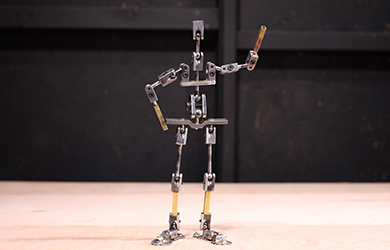

‘The proof is in the performance’ is perhaps an adage that best suits stop motion puppet making, and having spent many hours designing and fabricating this ball and socket armature, it was exciting to put it through its initial animation tests. Of course, these tests examine the fullest extent of the puppet’s armature as the inner skinning and exteriors can provide further obstacles to movement that will require separate design solutions. However, these initial tests were sound and demonstrated that the armature had good weight distribution, adequate range around the upper torso and shoulders, and good range throughout the puppet's armature to convey emotion via body language. All in all, a positive and satisfying outcome.

01/06/2022

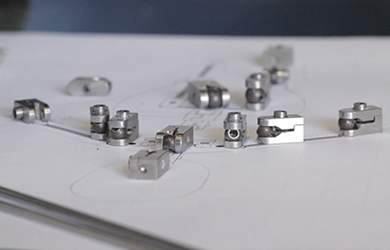

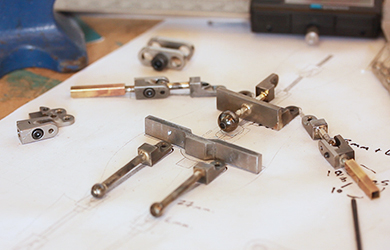

Whilst kit armatures are great for hobbyists and beginners, developing a skill set that enables a puppetmaker to design and make a bespoke ball and socket armature is fundamental for professional practice. This process requires multiple practical skills in machining and silver soldering, plus an eye for accuracy and considerable patience. Ball and socket fabrication is an art form, but it is engineering first and foremost, so a working knowledge of how materials behave, the stressors that the armature could endure whilst animating and also the range of movement required from the armature for the animated performance are key for a successful outcome. Essentially ball and socket armatures are tools for character animation, and all of the above factors must be considered in their design and build.

01/05/2022

Aesthetics aside, there are a few reasons I've elected to cast hands and boots for my latest stop motion puppet. As the puppet will be 21.5 cm tall, a ball and socket armature for the hands would be difficult to fabricate at such a small scale. Wire armature comes with a far greater risk of breaking as wire will fatigue and snap with repeated re-positioning over time. Plug-in hands are therefore the best choice to mitigate this risk, allowing for hands to be replaced on the stop motion puppet when needed. Further, this character will need to hold a variety of objects, so being able to permanently secure his hands to those would reduce the risk of these slipping or dropping through his hands when shooting the stop motion animation. Cheaper replacements, therefore make for the best option when these factors are considered, and using a mould to turn these out will ensure that his hands are consistent in all sequences. His boots also need to be a visually consistent pair and flexible as the puppet will be very active on set. Casting in a soft silicone which is highly pliable will give the greatest range of movement.

01/04/2022

Of course, in any professional practice it is vital to continue to develop expertise, and stop motion is no exception. The multidisciplinary nature of stop motion means there’s always plenty of new skills to master and I was fortunate to receive a grant for professional development from the West of England Combined Authority to enable me to extend my stop motion puppet fabrication skills into bespoke ball and socket engineering. Having come up with a turnaround character design for the puppet, the first step is to produce technical scale drawings that outline the armature build. These 2D plans allow for the armature to be visualised and the motion of the joints to be considered on paper before any hands-on fabrication begins. As such, I worked through several versions with consultancy support from Roos Mattaar to reach the finalised ball and socket armature design. It’s a fundamental and fascinating process, which ultimately ensures that the best animation performance can be delivered by the puppet on camera.